It is no secret that most air conditioners today are assembled in Asian countries, so the prestigious brands do not hide the origin of the equipment offered. If someone stubbornly convinces you that all air conditioners are made in Japan, you have good reason to doubt.

At the moment, mainly industrial and semi-industrial models are coming to us from the Land of the Rising Sun, as well as some new and expensive models, and until recently compressors were also produced in Japan.

Should this bother us?

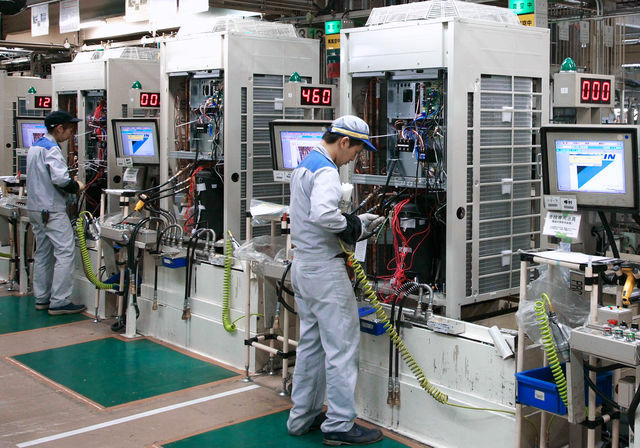

To answer this question, the reasons why the leading Japanese companies moved their production to Thailand, Malaysia, China and other Asian countries must be clear. First of all, it is cheap land for construction, low taxes and preferences, weak unions, as well as proximity to sources of raw materials and major markets. Contrary to popular stereotypes, the cost of labor plays almost no role, because the production itself is almost completely automated. Thus, in the factories of a leading company for the production of half a million air conditioners a year about 80 people are needed.

Control and quality are the concern of Japanese engineers and specialists, and packaging and loading is done by the local population. A similar picture is observed with other leading companies.

As a result, the quality of Japanese air conditioners produced in the company's factories inside and outside the country is absolutely identical. The reason for the emergence of Japanese factories in Europe is that it avoids high tariffs and fees to protect the domestic markets of these countries, which makes on-site production more profitable.