No modern building today, whether it is a business center, gym or other, can exist without a ventilation system and the use of spiral ducts. What are the modern round spiro pipes made of and their advantages and disadvantages, what are the products offered by Chernev Clima and their available diameters, where are they used and what are the ways of installation? All questions that excite every entrepreneur.

What are they made of

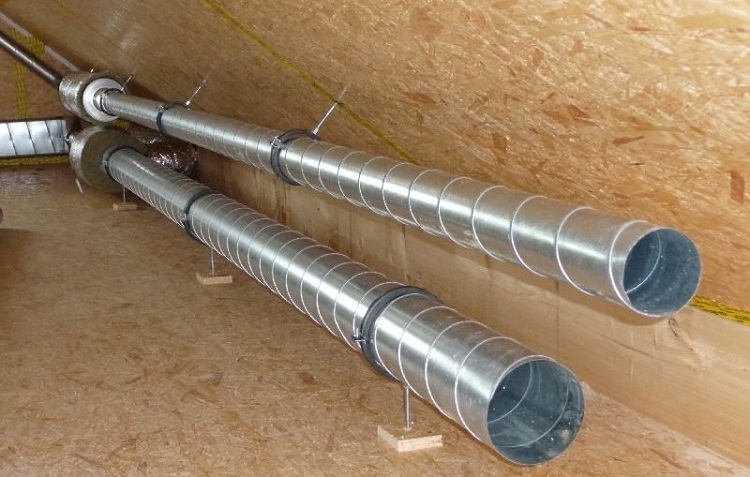

The main features of our air ducts are the low weight, allowing their installation, even in non-standard conditions. They are characterized by their high strength and resistance to aggressive influences. They are made of galvanized sheet metal or stainless steel with round shapes and different diameters.

Stainless steel air ducts can be spirally wound on a machine as well as made smooth by welding.

Spiral air ducts, also called spiro ducts, are made of galvanized sheet metal. They are spirally wound, which contributes to the additional strength of the pipes, allowing installation activities with much less fasteners. They are used for construction of pipelines and ventilation systems for aspirator, etc. The spiral air ducts are twisted from a thin galvanized sheet metal strip, the thickness of which is from 0.45 mm to 1 mm. It is the seam connecting the individual strips between them that makes up the spiral structure of the structure, playing the role of a reinforcing element.

Advantages and disadvantages

It is often necessary to build multi-meter ventilation systems that require the use and installation of tens of meters of ventilation ducts. Numerous connecting nipples and mounting brackets at a distance of no more than 1.2 m are used. Otherwise, smooth air ducts with fewer mounting and mounting brackets will deform at the joints under the pressure of their own weight, which will spoil the integrity and appearance of the installation.

With spiral ducts, this problem is completely solved, as each spiral adds extra strength to the structure, allowing the use of a standard length of 3 meters. This provides:

- Acceleration of the installation process;

- Saving money from the purchase of more fasteners, brackets and bolts;

- Their use for outdoor installation;

- More beautiful vision;

- Extreme lightness;

- Reducing noise levels;

- Enhancing effect of air masses, precisely because of its spiral structure.

Among the disadvantages, we can only note that due to the large length of the spiral air ducts, they are difficult and complicated to transport to the installation site by light commercial vehicles.

What diameters are there

The range of diameters of the spiral air ducts produced and offered by Chernev Clima can vary significantly: from f80 to f1250. Among the most used and preferred by our customers are the diameters from f125 to f450. Of course, if you need a specific diameter, which is non-standard and not provided for in factory production, the customer can take advantage of the option to make to order a specific size.

With us you can take advantage of available diameters: f80, f100, f125, f160, etc. to f450, as the sizes from f500 to a maximum f1250 are made to order.

Application

Spiral air ducts are also used in the construction of oil and gas pipelines. In this case, these products act as a protector of the inner protective shell. They are used in industrial buildings and shopping centers to build highly efficient ventilation systems. Spirochannels still play the role of airflow guides, leading it to a specific outlet. They are also used in private homes, industrial enterprises, business and residential buildings, shopping malls, high-rise buildings and small rural villas.

How to mount

Most often, spiral air ducts are installed to the walls, ceiling and in the spaces between the ceiling trusses. When planning and building metal ventilation systems, it must first be clarified whether a combination of pipes will be created, forming a system with a common outlet, or a separate independent mini-installation will be implemented for each room. Regardless of which of the two types you choose, the following rules must be observed: not less than 0.1m distance of the spiral air ducts from the ceiling, and to the walls and other objects - at least 0.05m.

The installation is usually done for the ceiling by means of studs and brackets used to fix the spiral air ducts. The studs must be taken in accordance with the diameter of the pipes, and rubber seals are used in combination with them to absorb vibrations. Thanks to the metal elements, the brackets are attached to the ceiling by means of a stud or other mechanism, the middle part is removed, the pipe is placed and the part is returned, fixing it by means of a tightening bolt.

For lengthening and splicing of the pipes are used special nipples, and reducers for changing the diameter, as well as silicones for improving the tightness of the system are provided.

Chernev Clima is a manufacturer

As a company with 30 years of market presence in the field of air conditioning and ventilation systems, we have the latest generation of modern and technologically innovative machines and equipment for the production of spiral air ducts. Our production bases are one of the largest and most modern in the country, which allows us to provide large production capacity, precise quality control and maximum cost optimization to offer affordable and affordable products.

As an official importer of branded air conditioning systems and heat pumps, Chernev Clima provides a place to purchase equipment for cooling or heating the home from the manufacturer, which guarantees the highest quality and excellent offers.